As the demand for detailed product data continues to rise, businesses are increasingly turning to advanced technologies to meet consumer expectations. Among these, barcodes play a crucial role in facilitating the unique identification of products and ensuring the seamless flow of accurate and detailed product information throughout the supply chain. While traditional 1D barcodes have served businesses well, 2D barcodes have emerged as powerful tools that offer much more data capacity and versatility. Data Matrix and QR Codes are two widely used 2-Dimensional barcode types that are transforming how product data is shared and verified, boosting consumer trust and reinforcing brand loyalty in the process. In this blog, we’ll explore the different types of 2D barcodes, understand their significance in modern business operations, and delve into the key differences between Data Matrix and QR Code to determine which is best suited for your needs.

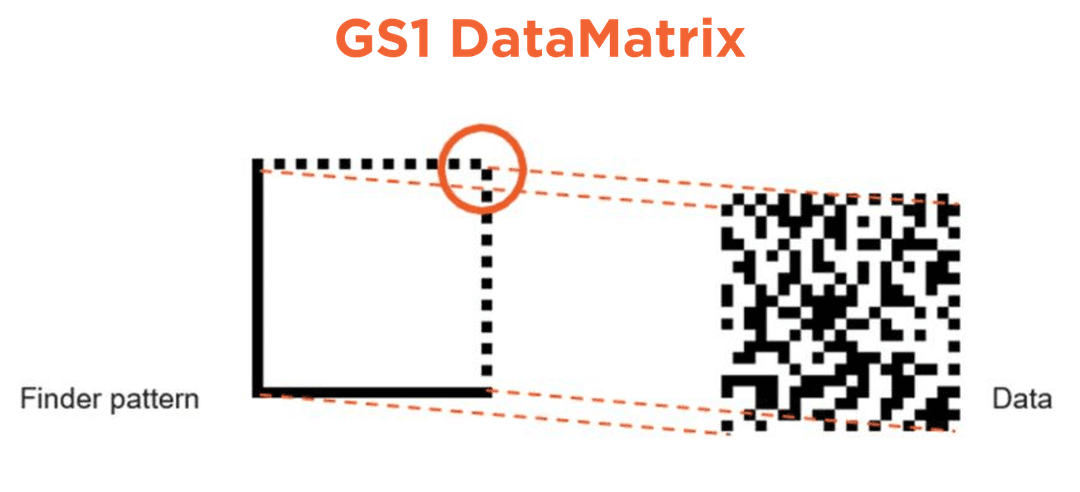

GS1 DataMatrix is a 2D/two-dimensional barcode which may be printed as a square or rectangular symbol. It is an ordered grid of dark and light dots bordered by a finder pattern. A DataMatrix Code is recognised by ISO/IEC because of its standardised structure. It is composed of two separate parts, the finder pattern and the encoded data itself. The GS1 DataMatrix barcode has a solid dark ‘L finder pattern’ used to ascertain the size, orientation, and disorientation of the symbol. Based on requirements like configuration support, available space on the product data, the printing process, etc., businesses can select either of the two.

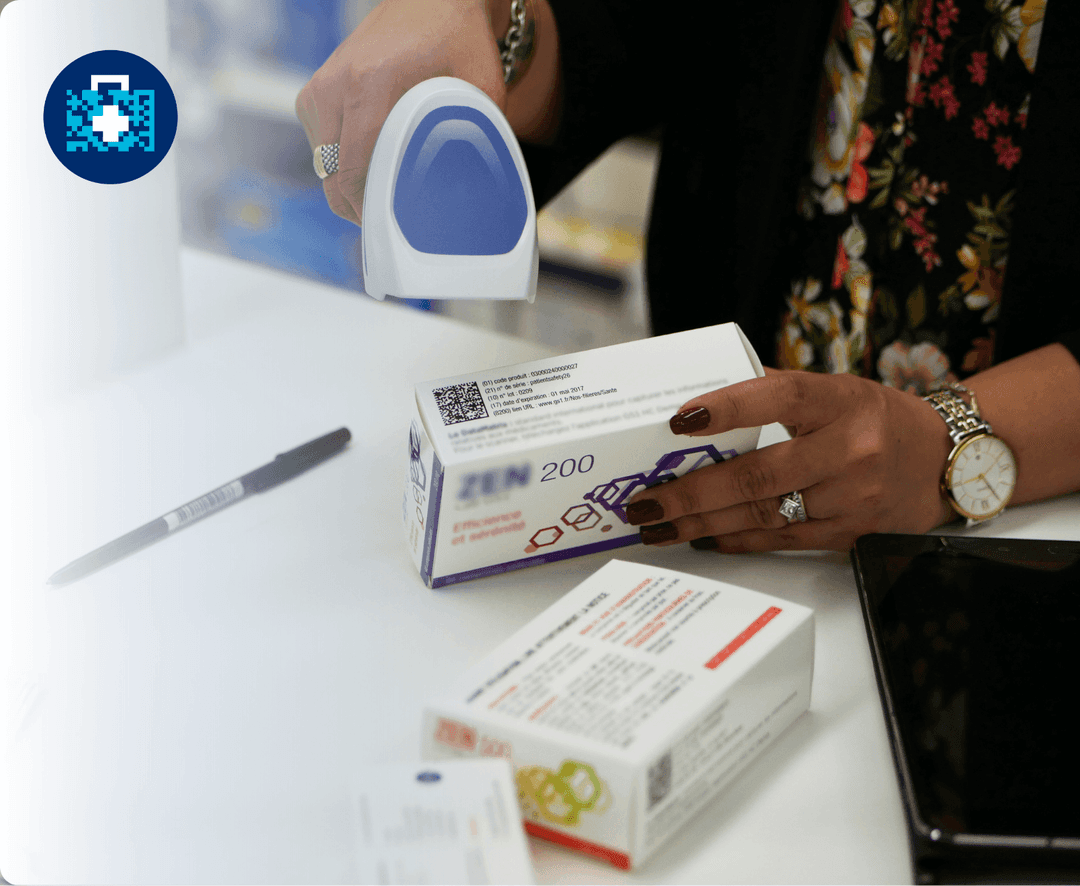

The GS1 healthcare community recommends GS1 DataMatrix as the only globally endorsed 2D/Matrix data carrier for product identification in healthcare. Its usage is deemed necessary when the scanning environment, data, and regulatory requirements do not support the application of a linear barcode. With numerous regulations requiring stakeholders to enable traceability, pharmacovigilance, and post-market surveillance of medical products, in addition to digital health advancement, there is an increased need to have scannable barcodes on medical products and their packaging.

When selecting a data carrier, it is important to use one that has widespread acceptance in the industry, to avoid cost and/or complexity. The GS1 DataMatrix barcode has been used for years in around 75 countries to meet traceability regulations. Several donor organisations require a GS1 DataMatrix barcode on pharmaceutical products they purchase. In addition, it meets UDI (Unique Device Identification) requirements in many countries and has the ability to encode the largest amount of identification data in the smallest amount of packaging space.

A QR code, or Quick Response code, is also a type of 2D barcode that can store significantly more information than a traditional 1D(linear) barcode. Its high data capacity and quick readability have made it a versatile solution for cataloguing, tracking, and identifying products and services across industries. The term ‘Quick Response’ stems from its ability to be scanned faster, offering a faster alternative to linear barcodes. Introduced in 1994 by Denso Wave, a Japanese automotive components manufacturer, the QR code was developed to address limitations of linear barcodes. Previously, companies had to rely on multiple 1D barcodes to convey complete product information. With the advent of QR codes, a single scan could provide all the necessary data, simplifying inventory and supply chain operations.

Today, QR codes have become extremely common. They appear on everything from product packaging to digital payment interfaces. We as consumers see them in our daily lives in one way or the other. A GS1 QR Code, because of its standardised structure, goes far beyond the basic use cases. It encodes the GTIN (Global Trade Item Number) along with other key product attributes like the manufacturing details, batch/lot number, expiry date, serial number, and more. In the FMCG sector, the adoption of QR codes is especially impactful. Multiple companies have integrated GS1 QR codes to meet regulatory requirements and provide detailed product information to consumers.

Take, for example, a single product SKU that may be linked to more than 20 manufacturing entities. Under FSSAI labelling compliance, all relevant information about these entities must be disclosed on the product packaging. However, space constraints often make this difficult, without compromising the visual design of the pack. A GS1 QR code offers an efficient solution. It allows brands to encode extensive data in a compact format, enabling full compliance while maintaining packaging aesthetics and consumer-friendly design.

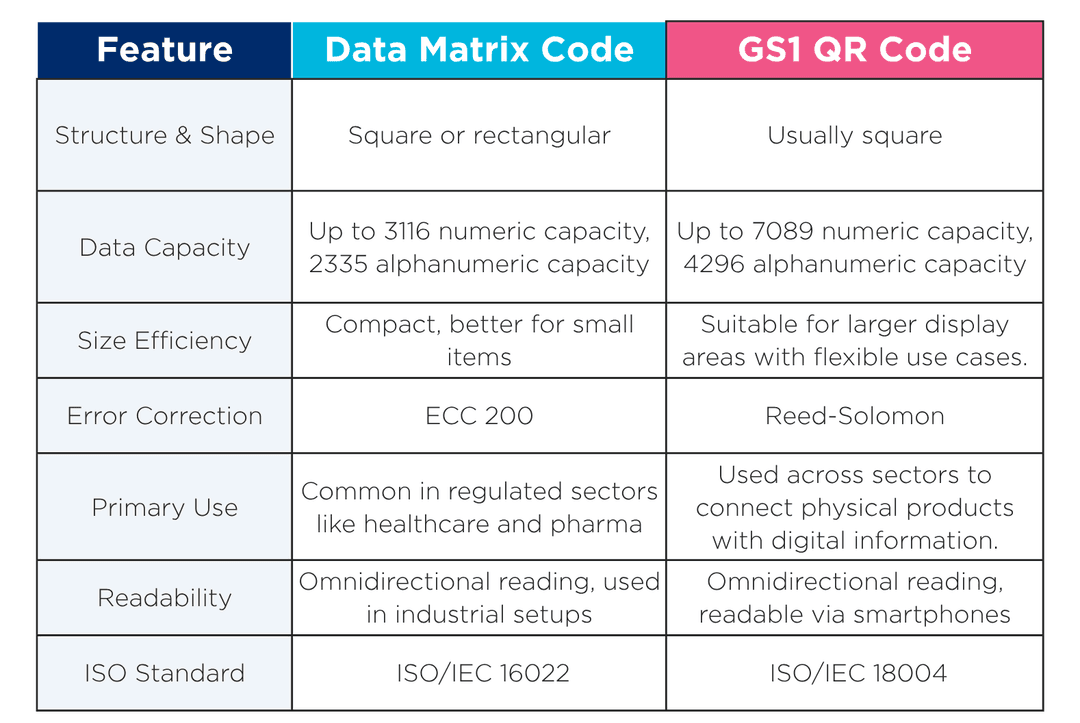

While QR Code and GS1 DataMatrix barcodes may appear similar, their structure, usage, and compliance with global standards vary, based on the application. Each serves a unique purpose, depending on the use case, whether it is consumer engagement or regulatory compliance. Understanding their distinctions helps organisations choose the right barcode for the product supply chain and consumer needs.

The GS1 DataMatrix barcode is used generally in the healthcare industry to uniquely identify medical products (devices and drugs).

A GS1 DataMatrix barcode can hold dynamic data in a very compact space. It can also allow encoding of variable data at high production speeds, making it the preferred choice of the healthcare industry.

The matrix in a barcode, like a DataMatrix, is used to encode information (e.g., product ID, batch number) in a compact, machine-readable format that can be scanned from any direction—even if partially damaged—ensuring accurate and fast data retrieval.

QR code stands for Quick Response Code

Yes, GS1 DataMatrix codes can be read by smartphones if they have a barcode scanning app or camera software that supports 2D barcode scanning.

Your email address will not be published. Required fields are marked *