The businesses continuously focus on making operations efficient. This blog explains how supply chain visibility across trading partners can help a company improve its operational efficiency and increase profitability.

Content

- What is Supply Chain Visibility?

- Application of Supply Chain Visibility

- Expiry Management

- Inventory Reconciliation

- Efficient Sales Forecasting

- Product Recall

- Restructuring Supply Chains

- How to achieve Supply Chain Visibility?

- Conclusion and Way Forward

What is Supply Chain Visibility?

Supply chain visibility refers to the ability of a business to know the details of the products available at each node in the supply chain, like a warehouse or a distribution centre. This includes accessing data about the number of products, their batches, manufacturing and expiry dates, etc.

Why Supply Chain Visibility is important?

Every business has a supply chain. It helps raw materials get to the factory and move products from the factory to the end consumers. In the global economy, supply chains are long, complex, and global. In a classic example, software from Bengaluru is embedded in a chip from Taiwan, which is put into a mobile in Noida along with other parts from Malaysia. The mobile is shipped to a customer in Vadodara via a warehouse in Ahmedabad. This is a complex supply chain involving many entities across different countries. The brand needs to have end-to-end visibility of the supply chain in order to efficiently manage its operations.

Inventory visibility at different nodes in the supply chain is important for businesses for expiry management, recall management, sales forecasting, and planning operations better, among many others. Once the business has end-to-end supply chain visibility, it can take measures to improve operational efficiency. Let’s explore various applications of supply chain visibility.

Expiry Management

All products have a defined shelf life. Depending on the type of product, it could be as short as a day for perishable foods, to a few years for some products, for example in case of cosmetics. Businesses need to implement expiry management processes to prevent losses. Without expiry management processes, a company could have a large number of items returned unsold due to expiry or near to expiry dates.

The businesses usually use a First Expiry First Out (FEFO) principle to reduce losses. To implement this effectively, they have to track the batches of the products as they are produced and released to the supply chain.

With inventory visibility, a business will know which batch of product is at which node in the supply chain. They would know the expiry date of all the products, enabling speedy movement of products, which are close to the expiry by giving some discounts, promotions, etc., if required.

Inventory Reconciliation

Businesses with complex supply chains would have products in different warehouses and with different trading partners throughout the supply chain. The number of products in the warehouses could be mapped in an inventory management system.

Real-time inventory visibility in the supply chain helps in inventory reconciliation. It can help in identifying and minimizing stock deficiencies, improving processes and preventing losses.

This can also help in reconciling mismatches between physical and system inventory. Furthermore, historical inventory data can help in determining the source of mismatch and correcting the same.

Efficient Sales Forecasting

Inventory visibility can help in sales forecasting. A company can get information on how fast a product is being sold and can adjust the production rate to meet the market demand. It also upgrades the readiness of the company to tackle unforeseen situations.

The company can also look at historical data of inventory of the product to forecast how the product sales would be in the coming months. If the inventory is running low, they can forecast and order more quantity to meet future demands.

Product Recall

Sometimes businesses are forced to recall or withdraw a product because of some unforeseen circumstances. The recall may be voluntary or because of a demand by the government.

Usually, product recalls are done at the batch level. To execute the same, brand owners must be aware of which batch of the product is available at which location in the supply chain. This is achieved through inventory visibility. Once the location of the faulty batches of products is ascertained, they can be recalled efficiently.

Restructuring of Supply Chain

Businesses have to continuously deal with dynamic situations. The supply chains should be flexible in order to resolve any situation. For example, there could be a sudden spike in demand for a product at a given location or a particular warehouse may become out of operation because of a natural disaster.

In such cases, real-time end-to-end supply chain visibility is helpful for the business to know from where it can divert the excess stock to fulfill the sudden spike.

How to achieve Supply Chain Visibility?

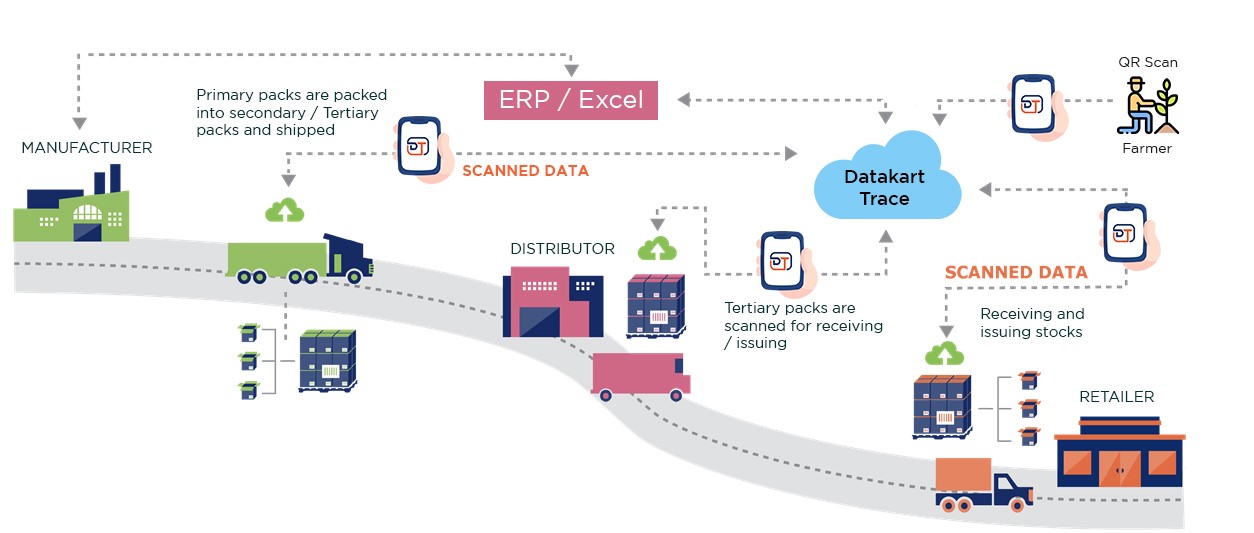

A company can achieve supply chain visibility using track and trace solutions. The first step is to get a unique identifier for each product SKU. They can use a Global Trade Identifier Number (GTIN) for product identification. GTINs are a globally unique product identifier issued by GS1. The GTIN can be encoded in barcodes and they can be printed on product packaging. The company can also use secondary and tertiary level barcodes for the unique identification of cartons and shipping containers.

When the products enter or leave the warehouse, the barcodes can be scanned and the data can be entered (with accuracy and in no time) in the inventory management system. The inventory management system can calculate the number of products using the scan data.

The company can use traceability solution like DataKart Trace to implement end-to-end inventory visibility in the supply chain. DataKart Trace is a seamless supply chain traceability solution that can be used by any industry or for any geography. It gives both upstream and downstream inventory visibility and enables real-time track and trace throughout the supply chain.

Conclusion and Way Forward

With end-to-end supply chain visibility, the company can improve the efficiency of operations. In the case study of Tata Steel, it has a division that sells doors and windows under the brand Tata Pravesh. They have a very complex supply chain. The supply chain includes multiple manufacturers, distributors and installation agencies, with more than 50 partners involved in all the transactions. They use the end-to-end traceability and supply chain visibility system of DataKart Trace from GS1 India to manage this complex supply chain.

Every company will have to determine how it wants to implement supply chain visibility. The solution would depend on the complexity of the supply chain, the number of products the company has, the shelf life of the products etc. The company can start with a simple barcoding solution. It can also work with GS1 India to develop more customized solutions which focus on the specific needs of the company. This could include other technology solutions like RFID tags and block chain.

The way forward for every company is to start investing in supply chain visibility solutions. This would help in improving the efficiency of the supply chain and increase the profitability of the company.